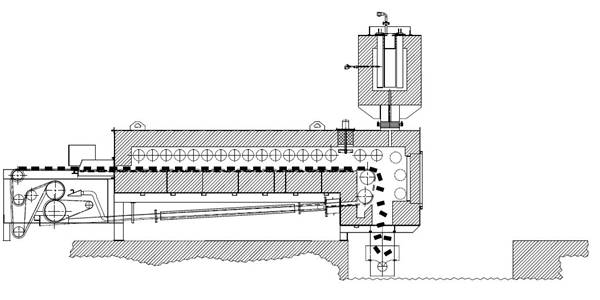

Retort Type Mesh Belt Furnace Type HT

Capacity max. 500 kg/h

For the heat treatment types tempering, annealing, soldering, nitrocarburizing, sintering under protective gas at temperatures up to 1,160°C in connection with gas rapid cooling or indirect water cooling section.

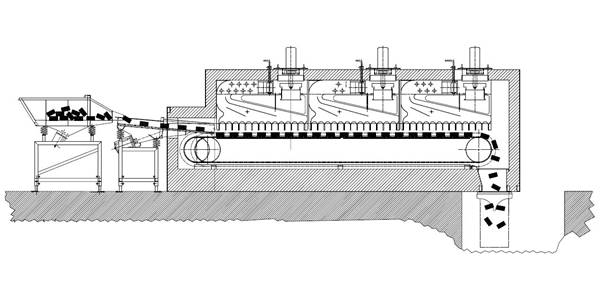

Mesh Belt Furnace Type FH-T

Capacity max. 500 kg/h

For austenitizing, gas carburizing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, salt or water. Belt run over SiSiC sliding plates. Wire belt conveyor with feed in cold zone . The wire belt conveyor is guided over a cooling channel and a water sealing.

Retort Type Mesh Belt Furnace Type: BLH

Capacity max. 500 kg/h

For austenitizing, carbonitriding, gas carburizing, nitrocarburizing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, salt or water. Process area surrounded by Ni/Cr retort. Fast change between atmospheres possible. Wire belt conveyor with feed in cold zone.

Mesh Belt Furnace Type FH-K

Capacity max. 1.000 kg/h

For austenitizing, carbonitriding, gas carburizing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, salt or water. Wire belt conveyor with feed in cold zone. The wire belt conveyor is guided over a cooling channel and a water sealing.

Mesh Belt Furnace Type FH

Capacity max. 1.000 kg/h

For austenitizing, carbonitriding, gas carburizing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, salt or water. Wire belt conveyor with feed in cold zone. Energy recovery by heat cuperation in the furnace inlet. Conveyor on anti-friction-bearing rollers.

Roller Hearth Furnace Type RMH

Capacity max. 500 kg/h

For austenitizing, gas carburizing, annealing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, gas or salt. The goods for heat treatment are transported over SiSiC rollers. Feed and discharge fast runs are possible.

Mesh Belt Furnace Type FHI

Capacity max. 2.500 kg/h

For austenitizing, gas carburizing under protective gas at temperatures up to 950°C in combination with quenching in oil, polymer, salt or water. Cast link conveyor circulates through interior of furnace. Feeding via optional inlet gate / vibratory chute in the heated zone. Conveyor on anti-friction load-bearing rollers.

Mesh Belt Furnace Type LGO

Capacity max. 500 kg/h

For solution annealing and artificial ageing of aluminium at temperatures up to 650°C in conjunction with water quenching. Temperature uniformity in the holding zones guaranteed at max. +/- 3°C. Cast link conveyor circulates through the interior of the furnace. Feeding via vibratory chute in the heated zone.