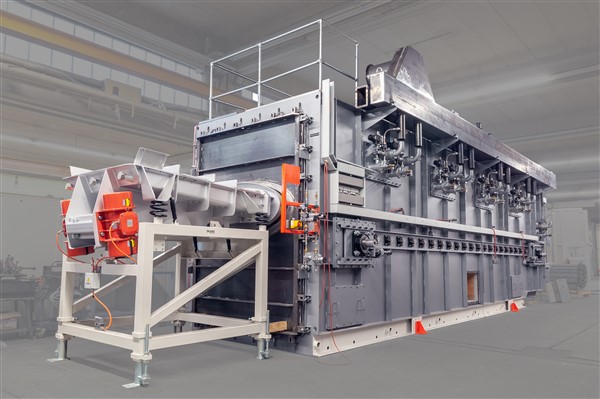

Features

- Temperature operating range 400°C – 950°C

- High-temperature furnace without retort, internal furnace chamber

- insulation

- Cast apron feeder, extremely stable design

- Support roller conveyor for gentle passage of the furnace belt

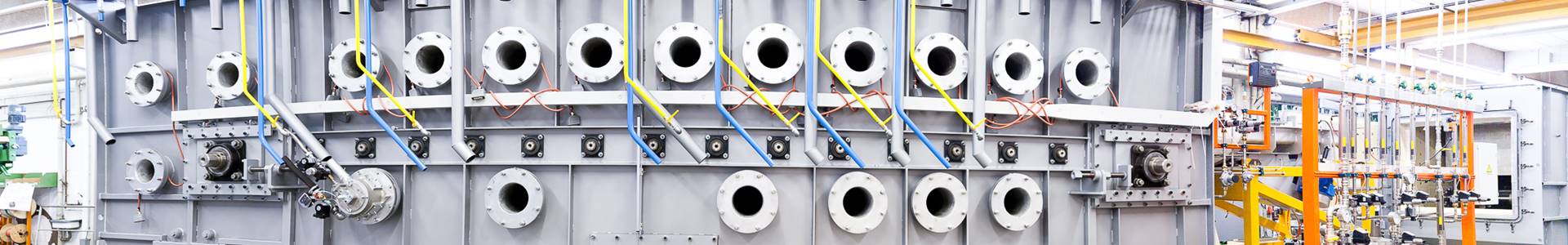

- Furnace chamber is pressurized with protective gas/reaction gas

- Gas (Reku burner) or electrically heated

- Hot gas circulation for homogenization of the atmosphere and for

- uniform

- Gas admission to the material

- Material feed takes place inside the furnace chamber

- Separation of individual gassing zones possible

Power ranges and processes

- 200 – 2000 kg/h Austenitizing (hardening)

- Bainitizing (intermediate level quenching and tempering)

- Carbonitriding and carburizing only possible to a limited extent

Line Arrangement | Companion Equipment

- Automatic loading and unloading equipment

- Vibratory transfer systems within the equipment line#

- Automated transport system outside the equipment line

- Pre-washing machines with dephosphating, intermediate washing

- machines

- Oil, salt, polymer or water quenching equipment

- Tempering and expansion furnaces

- Integrated and external protective gas generators

- Switching and control systems with SPS control

- Process data acquisition system